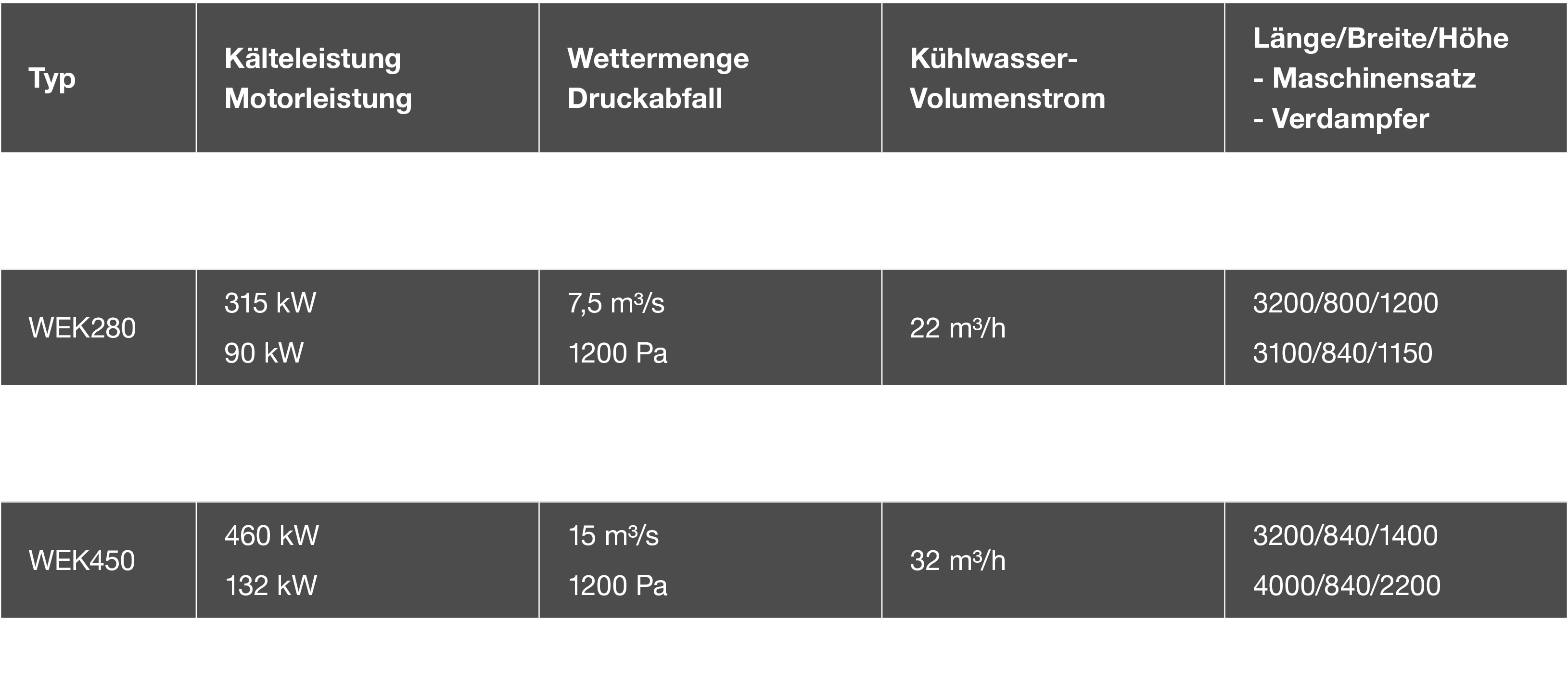

Air cooling machines

Air cooling machines generate cooling capacity directly at the location in which they are in use, reducing the temperature in the immediate vicinity. The advantage is that the capacity of the air cooling machine can be used to its fullest extent. In contrast to cold water systems, these machines do not require the installation of insulated cooling water pipelines and no cooling capacity is wasted.

Air cooling machines are particularly suitable in cases where only a limited number of operating points need to be cooled and a centralised cooling system is not possible. Herco provides air cooling machines with range of cooling capacities from 230 kW to 460 kW.

Cold water machines

Cold water machines are set up in a central position and supply several operating points from there. Centralised systems like this are particularly cost-effective. Another advantage of cold water machines is that they are easier to maintain than others because the technology for the entire system is in one location.

Cold water machines are available with high-pressure condensers that increase the system’s capacity even further. The heat energy absorbed underground by the cold water machines is moved directly above ground through shaft pipelines. From there, it dissipates into the atmosphere.

Air cooling units

Air cooling units are used in connection with cold water machines. They are supplied with cold water through insulated cooling water pipelines and absorb the heat energy at their respective operating points. The air cooling units then deliver the heated water back to the central cold water machine where it is pumped up above ground.

In contrast to air cooling machines, air cooling units do not provide their own cooling capacity. For this reason, air cooling units are considerably smaller and easier to install.

Longwall air coolers

Longwall air coolers are specialised cooling units. They are installed directly in the longwall itself if the mine air cooling system at the face of the wall is not able to reduce the temperature.

Depending on the application and application site, two types of heat exchangers are used in longwall air coolers. In coolers with tube bundle heat exchangers, the air flows through a group of tubes immersed in cold water. Smooth copper tube heat exchangers are spiral-shaped and are also used in our air heat exchangers.

Re-coolers

Re-coolers are used to remove the heat energy absorbed by air cooling machines and cold water machines. In re-coolers, cooling capacity is generated by water evaporation. If the water supply is not sufficient for heat dissipation, re-coolers can also transfer the heat to a mine air ventilation outflow.

High-pressure/low-pressure heat exchangers

High pressure is required in order to connect the installations located above and below the ground into one cooling circuit. This is the only way to compensate for the difference in height if, for example, a cold water machine located above ground is supplying an air cooling unit below ground.

In order for the cooling circuit below ground to operate with low pressure, it must be removed from the high-pressure circuit. The connection between these two circuits is created with a high-pressure/low-pressure heat exchanger.

The water from above ground flows through the high-pressure section of the heat exchanger and the water from the underground circuit flows though the low-pressure section. The high-pressure/low-pressure heat exchanger must be able to withstand high operating pressure. For this reason, the standard high-pressure/low-pressure heat exchangers are designed for a pressure of 160 bar.

Specialised solutions

Air-cooled systems for cooling fluids

In cases where no water is available for cooling motors, electrical components or hydraulic fluids, air-cooled systems are an appropriate solution.

Air-cooled systems by Herco are very compact and consist of a steel frame with covering panels. The systems include a pump unit with an integrated fluid buffer which transports the heat energy to the heat exchanger. There a fan cools the fluid.

Heat exchangers for cooling gas in connection with cold water systems

Special heat exchangers are used to cool and dehumidify gases simultaneously. When used to extract mine gas, for example, these heat exchangers offer significant advantages. Decreasing the quantity of water also reduces corrosion and drops in pressure.

Herco gas coolers have classic, smooth copper tube heat exchangers. As an alternative, a tube bundle heat exchanger made of stainless steel can be used to eliminate the possibility of corrosion.